QJ 50 and 80 series gas relays

The QJ series gas relay is a protective device used in on-load tap changers of oil-immersed transformers. The gas relay is installed on the connecting pipe between the transformer tank cover and the oil tank, and can be equipped with a gas guide pipe to realize ground exhaust and sampling. When an internal fault in the transformer causes the oil to decompose and generate gas or causes oil surge, the relay contacts will operate to connect the specified control circuit, and promptly issue a signal or automatically cut off the distribution transformer or the transformer itself.

Keywords:

Category:

Product Description

Product Introduction

The QJ series gas relay is a protective device used in the on-load tap changer of oil-immersed transformers. The gas relay is installed on the connecting pipe between the transformer tank cover and the oil tank, and a gas guide pipe can be installed to achieve ground venting and sampling. When an internal fault in the transformer causes the oil to decompose and generate gas or causes oil surge, the relay contacts will operate to connect the specified control circuit, and promptly issue a signal or automatically cut off the distribution transformer or the transformer itself.

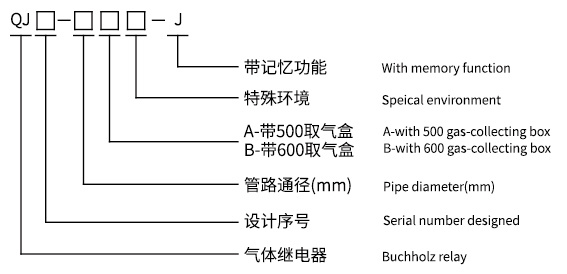

Model Description

Example 1: QJ4-80ATH-J indicates a gas relay with memory function, designed for the 4th time, with a pipe diameter of 80mm, a 500 gas sampling box, and used in humid and hot regions.

Example 2: QJ3-50TH indicates a gas relay designed for the 3rd time, with a pipe diameter of 50mm, and used in humid and hot regions.

Special Environments

“TH”- For humid and hot regions

“TA”- For tropical dry regions

Unspecified general type

Operating Conditions

Operating temperature: -45℃~100℃

Installation: The relay pipeline axis should be parallel to the transformer tank cover. The end leading to the oil tank can be slightly higher, but the inclination of its axis to the horizontal plane should not exceed 4%.

Product Model

| Model | Accumulated Gas Volume (mL) | Oil Speed Setting Range (m/s) | Factory Setting Oil Flow Rate (m/s) | Number of Outlets |

| QJ1-50 | 250-300 | 0.6-1.2 | 0.8±0.1 | 1 |

| QJ3-50 | 250-300 | 0.6-1.2 | 0.8±0.1 | 2 |

| QJ4-50 | 250-300 | 0.6-1.2 | 0.8±0.1 | 1 |

| QJ12-50 | 250-300 | 0.6-1.2 | 0.8±0.1 | 2 |

| QJ13-50 | 250-300 | 0.6-1.2 | 0.8±0.1 | 2 |

| QJ16-50 | 250-300 | 0.6-1.2 | 0.8±0.1 | 2 |

| QJ1-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 1 |

| QJ2-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 1 |

| QJ3-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 2 |

| QJ4-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 1 |

| QJ6-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 2 |

| QJ12-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 2 |

| QJ13-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 2 |

| QJ16-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 2 |

| QJ19-80 | 250-300 | 0.7-1.5 | 1.0±0.1 | 2 |

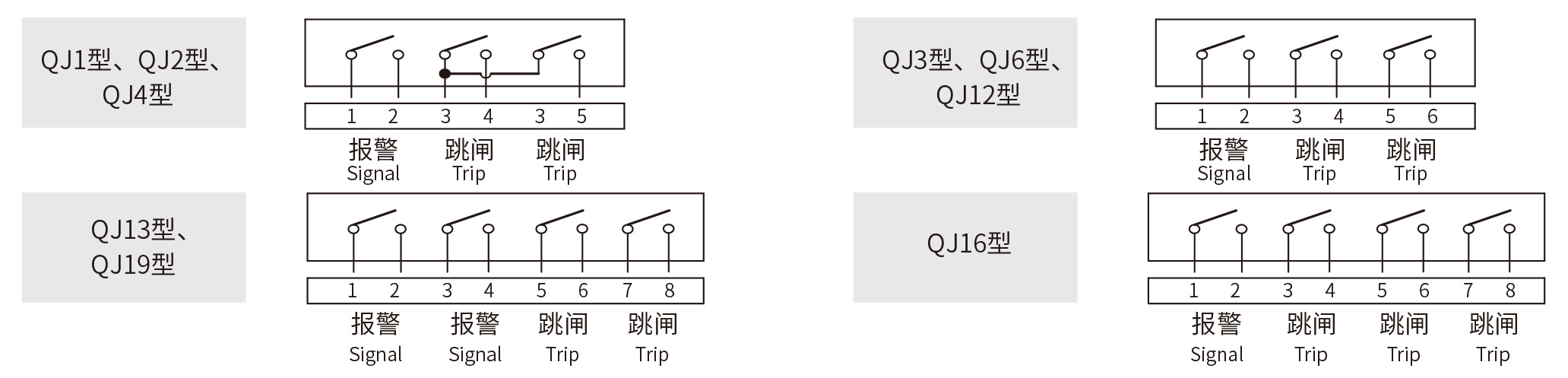

Wiring Diagram and Contact Capacity

| Power Supply Type | Operating Voltage | Operating Current | Description |

| DC | 220V | 0.3A | Time Constant S≤5×10-3 -3 S |

| AC | Power Factor Cos φ≤0.6 |

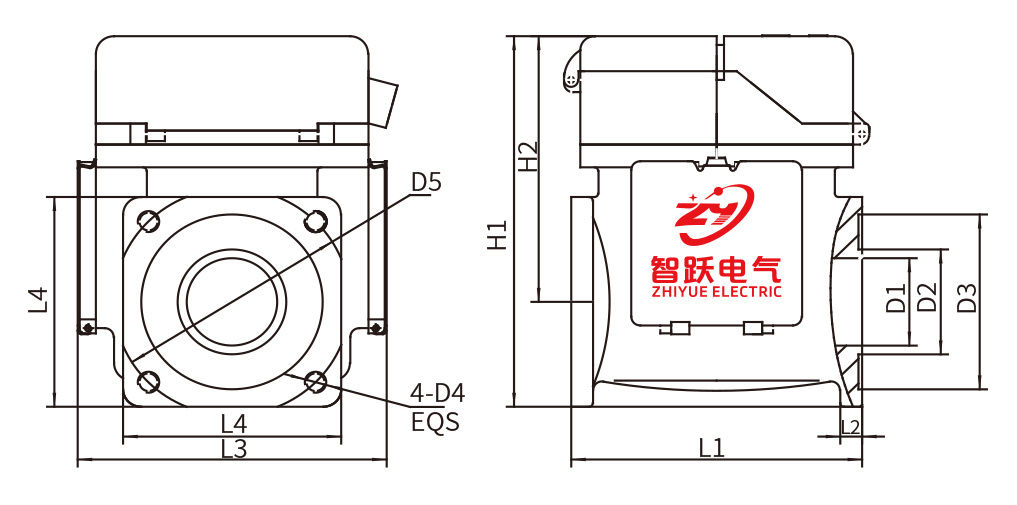

Appearance and Installation Dimensions

| Model | D1 | D2 | D3 | D4 | D5 | H1 | H2 | L1 | L2 | L3 | L4 |

| QJ1-50 | φ50 | φ60 | φ100 | M12 | φ130 | 212 | 152 | 160 | 12 | 170 | 120 |

| QJ3(4/12/13/16)-50 | φ50 | / | / | φ14 | φ125 | 215 | 154 | 185 | 15 | 170 | 125 |

| QJ1-80 | φ80 | φ85 | φ110 | M12 | φ130 | 212 | 152 | 160 | 12 | 170 | 120 |

| QJ2(3/4/6/12/16/19)-80 | φ80 | / | / | φ14 | φ125 | 215 | 154 | 185 | 15 | 170 | 125 |

Related Products

Get a quote